Radial Packaging System

HTW Radial Packaging Systems

The HTW line of Radial Roll Packaging Systems are proven on a daily basis in our customer’s plants. We have been providing roll packaging solutions to our customers since 1982. During this time, we have developed the HTW-100, -200, and -300 Series of Radial Wrappers. With both Low-Profile and Overhead styles, Mechadyne offers the most flexibility in the industry.

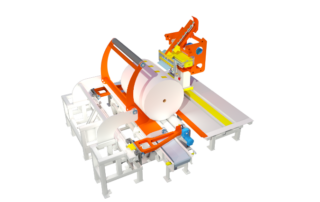

The most popular model of Mechadyne’s HTW Series Film Roll Packaging Systems, the HTW-100 is also the lowest priced for a complete wrapping system.

With throughput rates up to 30 Rolls Per Hour, the operator only has to attach the film and press “start”. The included PLC Control System handles the rest of the wrapping cycle, including film cutting! Adding to the many features found on the HTW-100, the wrapping cycle parameters are completely adjustable …# of end wraps, edge overhang, # of layers and more…

Integrated in to a packaging system, or as a stand-alone roll packaging station, the HTW-100 is a perfect solution for semi-automatic applications, including pulp and paper, nonwovens, textiles, floor covering or converting. Available in Low Profile (LP) or Overhead (OH) styles, the HTW-100 can be installed above floor or in-floor, and configured to meet most product flow requirements.

Typical roll specifications for an HTW-100 Film Roll Packaging station are:

Roll Diameters from 10″ up to 60″ (smaller and larger in many cases)

Roll Widths from 12″ up to 120″ (longer in many cases)

Roll Weights from 100 lb. up to 6,000 lb.

Film Roll up to 30″ Wide x 18″ OD and 3 mil thickness

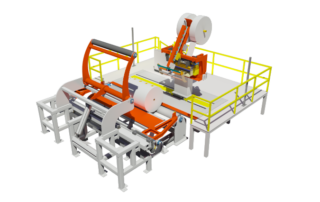

Flexibility is the key word when describing the HTW-200 Series. Whether a fully automatic or a semi-automatic Film Roll Packaging operation that best fits your application, Mechadyne’s HTW-200 Series may be your very best value. If your current needs do not include a fully automatic packaging system, the semi-automatic HTW-200 is an economical consideration. When your needs call for full automation, simply retrofit the Auto Film Start (AFS) option to your existing HTW-200 and you have a packaging system that meets your increased demands.

The HTW-200 is an extraordinarily rugged and dependable machine, capable of wrapping rolls at a rate of up to 60 Rolls Per Hour. It can be installed in virtually any plant location and can be integrated into most existing roll handling systems. Available in either an Overhead (OH) or a Low Profile (LP) style, the HTW-200 can be installed above floor or “in-floor” and configured to meet your specific requirements for product flow.

Typical roll specification for an HTW-200 Film Roll Packaging stations are:

Roll Diameters from 24″ up to 84″ (smaller and larger in many cases)

Roll Widths from 12″ up to 120″ (longer in many cases)

Roll Weights from 250 lb. up to 10,000 lb.

Film Roll up to 40″ Wide x 30″ OD and 3 mil thickness

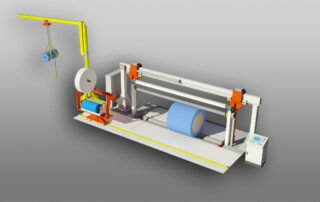

Throughput rates of up to 90+ Rolls Per Hour

Film Capabilities of up to 30″ OD x 40″ Wide

Automatic Film Start, Cut, and Close

Electronically controlled “Pre-stretch” & “Tension”

Servo Motor controlled Turning Rollers & Film Dispensing

“Touch” Screen Operator Controls

Diagnostics Display

And more…Whether it’s an Overhead or a Low Profile style, the HTW-300 Series can be installed above floor or in-floor and can be configured to meet your specific requirements for product flow.

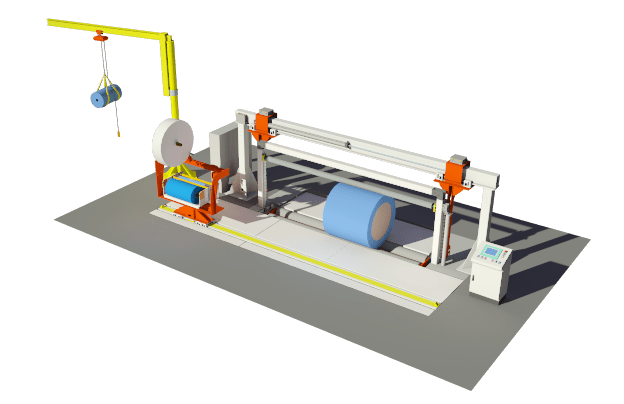

To watch the HTW-300 Series wrap a roll is simply fascinating, not to mention that you don’t want to “blink”, or you could miss the race.

Typical specifications for an HTW-300 Film Roll Packaging station are:

± Roll Diameters from 24″ to 84″

± Roll Widths from 12″ to 120″

± Roll Weights from 250 lb. to 10,000 lb.

± Film Roll up to 40″ Wide x 30″ OD and 3 mil thickness