Roll Packaging

. . . trust Mechadyne to protect your products . . .

With three different methods of packaging your products, the Mechadyne HTW Radial, AW Axial, and VTW Vertical Series provide a complete solution for all of your roll packaging needs!

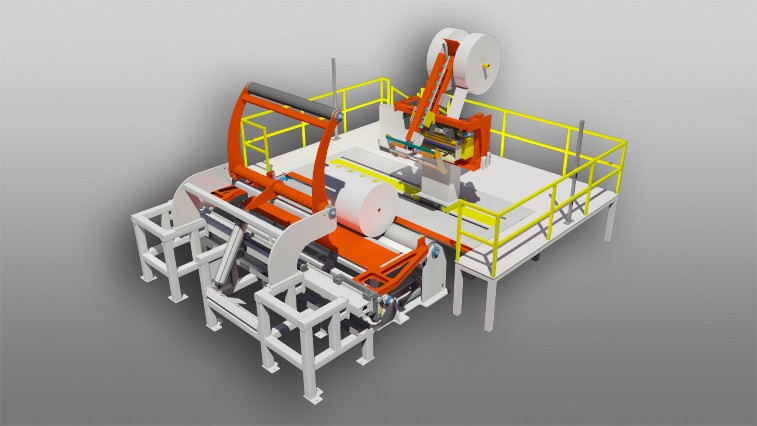

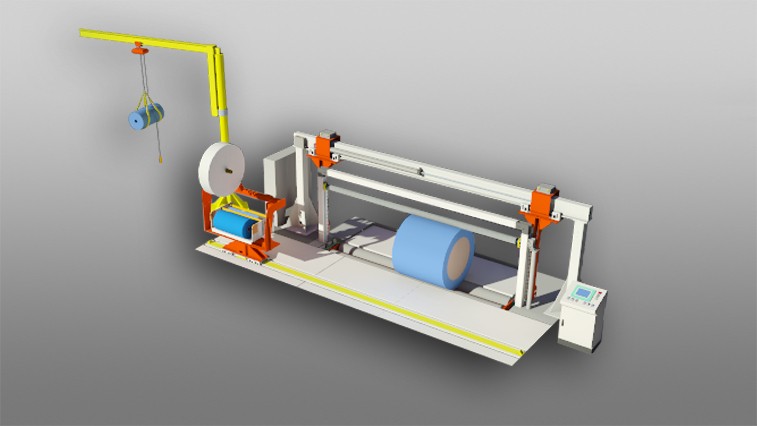

AW Axial Packaging Systems

Mechadynes AW line of Axial Roll Packaging Systems was introduced to meet an ever-growing need by our customers to have complete film end coverage on their rolls and eliminate the need for end discs. Commonly known as “cocoon wrapping”, we listened to our customers regarding their requirements and developed the AW Series of Axial Wrappers with both Rotary Arm (RA) and Rotary Table (RT) styles. The AW Series provides both semi-automatic and automatic systems to meet our customers production needs. We used the same technology that has made our HTW Radial Wrapping Series so successful including providing both film package tension and film pre-stretching features to allow our customers to control both their package appearance and package cost.

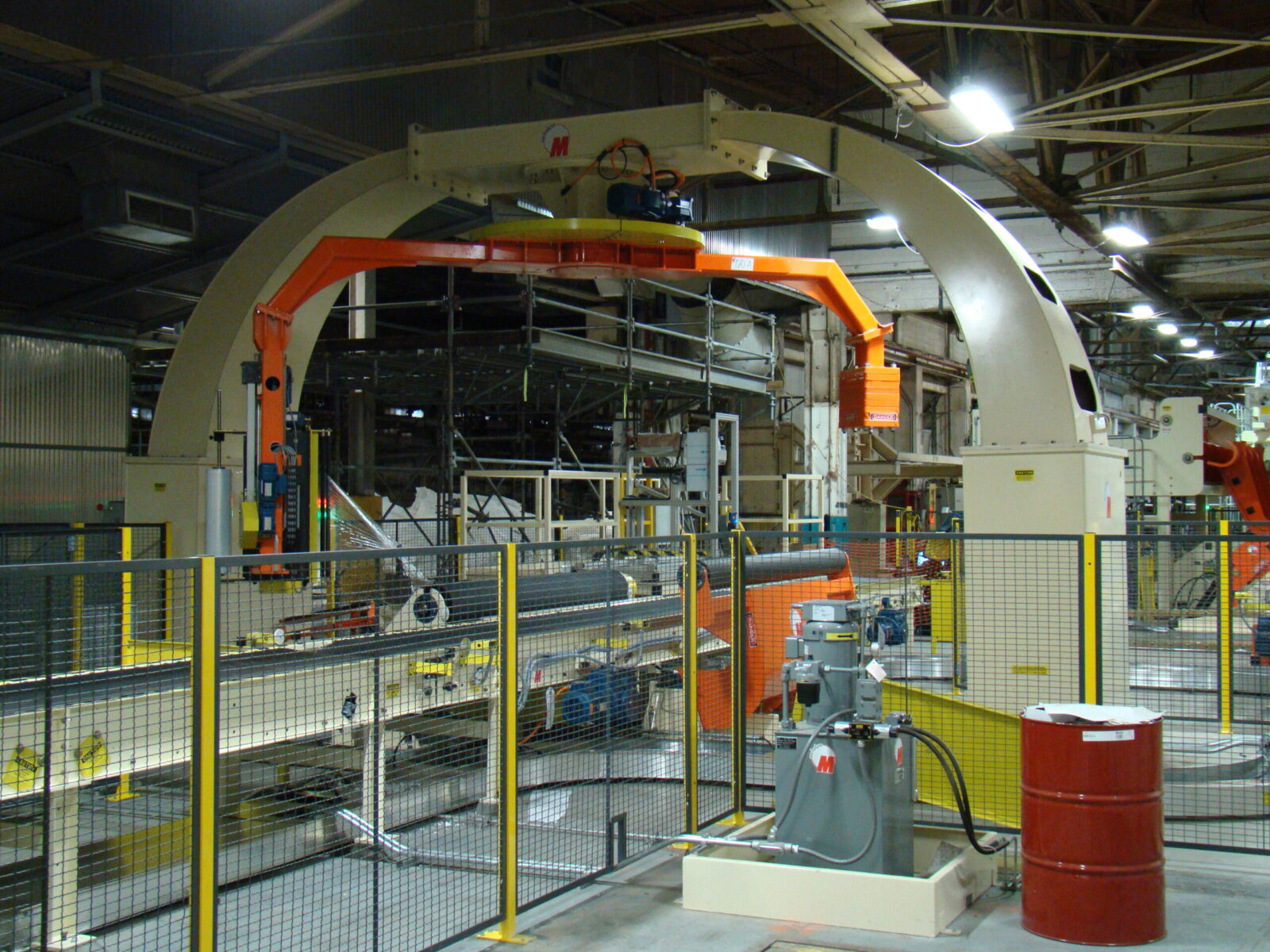

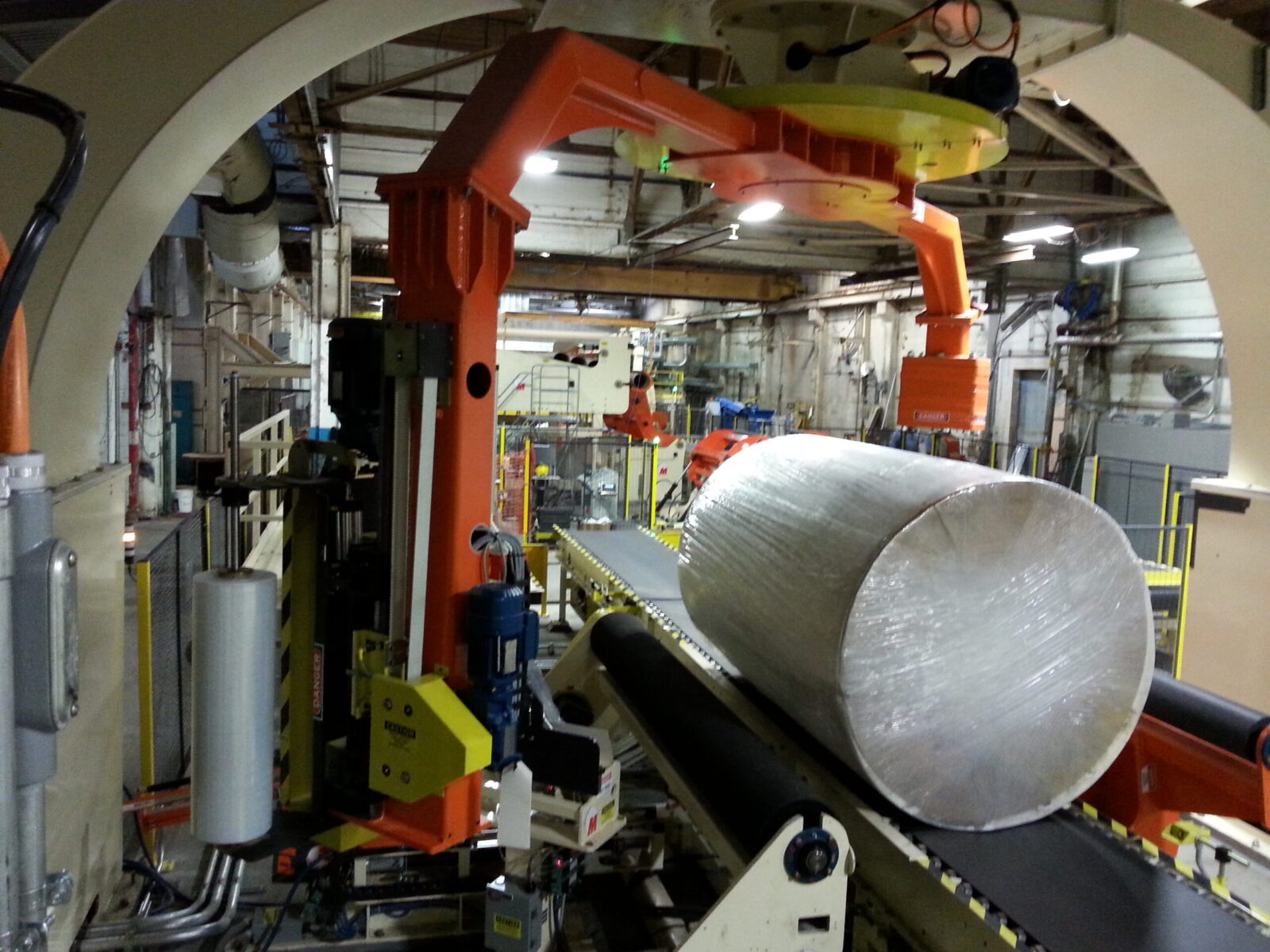

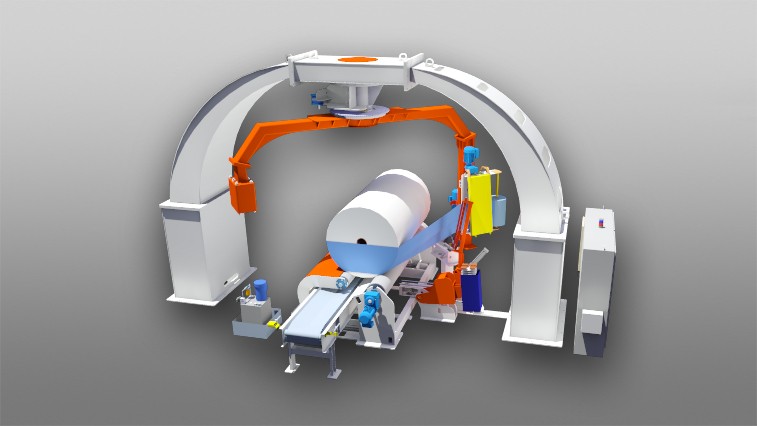

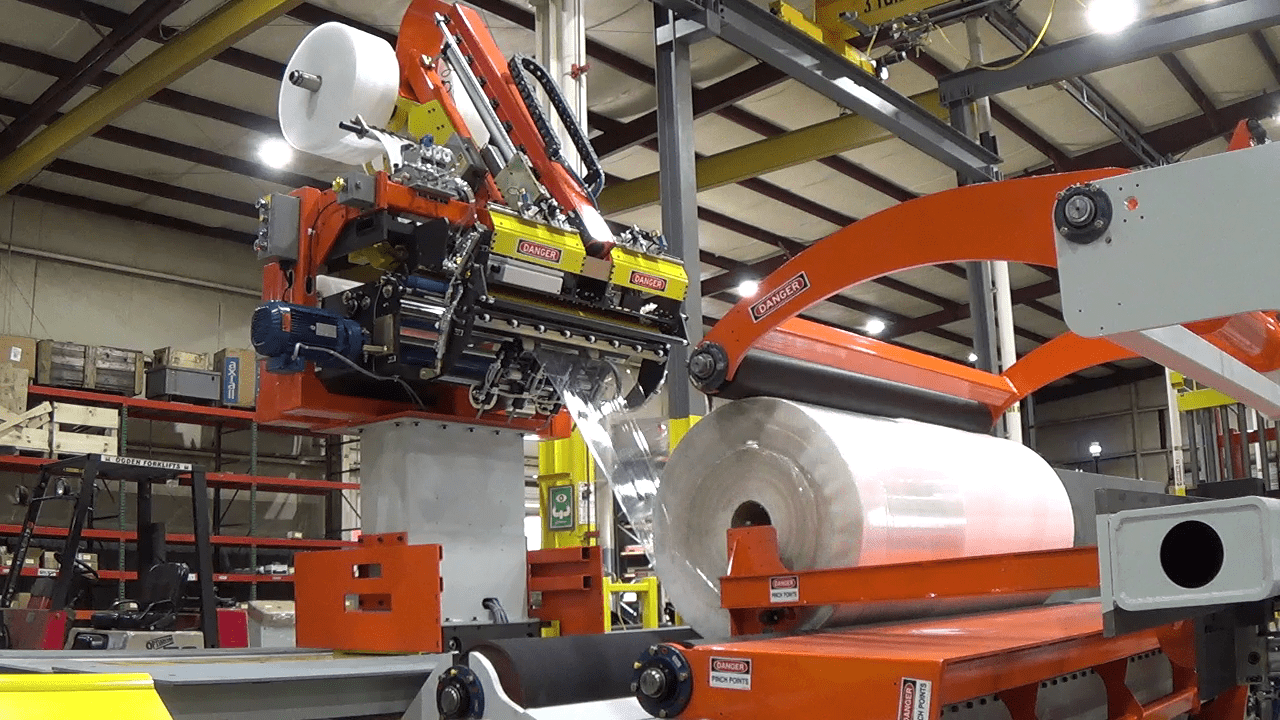

HTW Radial Packaging Systems

The HTW line of Radial Roll Packaging Systems are proven on a daily basis in our customer’s plants. We have been providing roll packaging solutions to our customers since 1982. During this time, we have developed the HTW-100, -200, and -300 Series of Radial Wrappers. With both Low-Profile and Overhead styles, Mechadyne offers the most flexibility in the industry.

VTW Vertical Packaging Systems

Like the Mechadyne HTW Series of Radial packaging systems which is designed for horizontal wrapping of rolls, the VTW line of Wrapping systems offer these same features but with the roll in a vertical orientation. Integrated in to a packaging system, or as a stand-alone roll packaging station, the VTW Wrapping Systems are a perfect solution for semi-automatic or automatic applications, including pulp and paper, nonwovens, textiles, floor covering or converting. Available in Rotary Arm (RA) or Rotary Table (RT) styles, the VTW systems can be configured to meet most product flow requirements.